Achieving Digital Transformation: Mastering Traceability and Sustainability in Supply Chains

Introduction

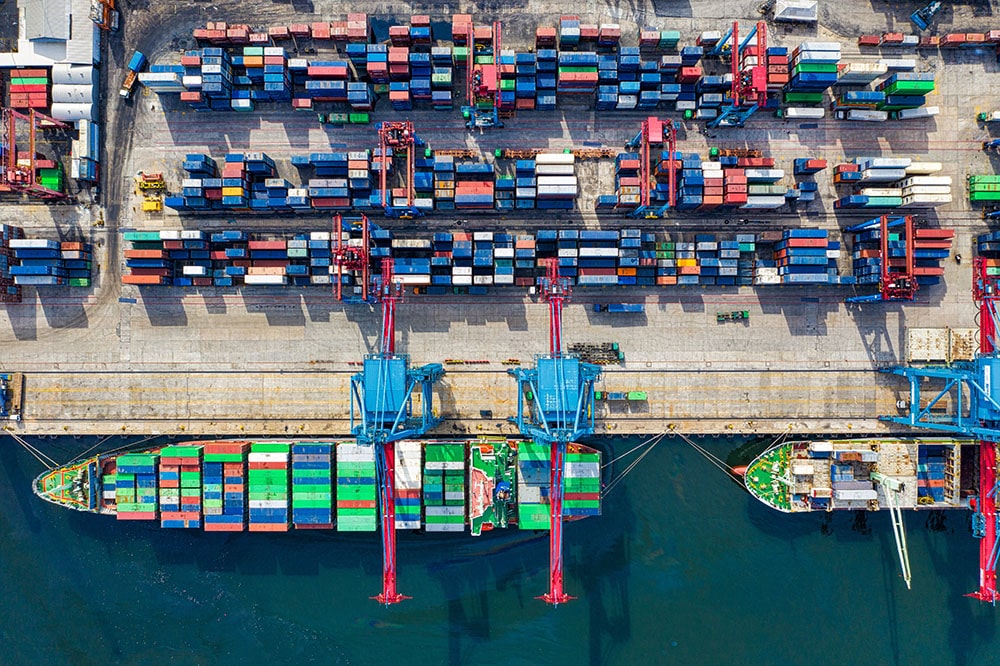

In today’s competitive global market, implementing traceability and sustainability initiatives within supply chains is increasingly crucial. Digital transformation serves to enhance supply chain performance and resilience by harnessing technological innovations. This article’s objectives are to discuss the role of traceability and sustainability in supply chains, explore the benefits and challenges of implementing these initiatives, and suggest strategies for success in a digitally transformed landscape.

The Power of Traceability in Supply Chains

What is Supply Chain Traceability?

Traceability refers to the ability to track and monitor products and their components as they travel through the supply chain—from raw material sourcing and manufacturing to distribution and consumption. It involves the systematic data collection and analysis during each phase, ensuring product authenticity, safety, and compliance with regulations. Accurate traceability enables businesses to gain a deep understanding of their products, paving the way for efficient supply chain management. It further reduces potential instances of fraud, illicit activities, and unethical practices in the supply chain[13%5E].

The Benefits of Traceability and Transparency

Implementing traceability and transparency initiatives offers a range of benefits to businesses:

- Sustainability: Traceability fosters a more environmentally and socially responsible supply chain, promoting sustainable practices and reducing the ecological footprint of products[^1^]. Sustainable supply chains not only help our environment but also improve brand standing and customer loyalty.

- Risk Management: Achieving transparency enables businesses to identify and mitigate potential risks before they escalate[^2^]. It can help to avoid potential disruptions in the supply chain, maintain brand reputation and image, and keep businesses running smoothly.

- Regulatory Compliance: Accurate tracking of products and components can ensure compliance with global regulations while reducing the likelihood of product recalls[^3^]. Regulatory compliance is necessary for both access to markets and avoiding costly penalties.

- Consumer Confidence: Enhanced traceability can increase consumer trust in the products, strengthening brand loyalty and driving sales[14%5E]. The growing consumer trend of demanding increased transparency means that businesses who embrace traceability initiatives can gain a competitive advantage.

Digital Transformation as the Catalyst

Technology and Innovation

Various technologies, such as the Internet of Things (IoT), and Blockchain, enable traceability in digitized supply chains. IoT devices can log and communicate real-time supply chain data, enhancing end-to-end visibility[^4^]. IoT provides the necessary automated monitoring required in today’s complex global supply chains and can help track vital information such as product location, temperature, and other environmental factors.

Blockchain solutions can securely store and verify data throughout the chain, further ensuring integrity[^5^]. Through decentralization and consensus, blockchain technology helps create an incorruptible and transparent data storage structure. This level of data accuracy and transparency is particularly beneficial in ensuring the quality and safety of products in industries such as pharmaceuticals and food & beverages.

Additionally, technology like Radio Frequency Identification (RFID) and Global Positioning System (GPS) has become essential for physical asset tracking[15%5E]. These technologies provide real-time updates on the location of products and components, further enhancing traceability.

Data Acquisition and AI-Driven Insights

Data acquisition, analysis, and interpretation are crucial in supply chain decision-making. Artificial Intelligence (AI), machine learning, and predictive analytics can process vast amounts of data, generating valuable insights to enhance operational efficiency and competitiveness[^6^]. Through the analysis of data patterns, AI-driven software can uncover supply chain inefficiencies and help predict potential disruptions. In addition, AI technology allows for accurate forecasting and demand planning, leading to improved inventory management and reduced costs.

Challenges in Implementing Traceability Initiatives

While traceability initiatives promise significant benefits, companies often face challenges in implementation:

- Cross-functional collaboration: Successful traceability initiatives require strong collaboration between multiple departments, suppliers, and stakeholders[^7^]. Implementing a new traceability system often necessitates changes to established processes, requiring buy-in from various parties and clear communication.

- Technological investment: Companies must invest in technology and infrastructure upgrades, while managing the potential disruption in business processes[^8^]. This presents a significant challenge, especially for smaller businesses with limited resources. One approach is to utilize Software-as-a-Service (SaaS) and cloud-based platforms, which can be cost-effective and highly scalable.

- Data management and security: The sheer volume of data generated throughout the supply chain can create management challenges and raise security concerns[^9^]. Ensuring data remains accurate, consistent, and secure is of utmost importance.

Strategies for Developing a Successful Traceability Initiative

Supplier Collaboration and Connectivity

Establishing strong relationships with suppliers and fostering a collaborative environment can lay the foundation for successful traceability initiatives. Businesses must work closely with suppliers to set clear expectations about data sharing and reporting. Networking tools can facilitate real-time data sharing, enabling businesses to make informed decisions and minimize risk[^10^]. In addition, transparency in the supplier selection process can help ensure that all parties within the supply chain are committed to traceability and sustainability principles.

Supply Chain Mapping and Visibility

Creating comprehensive supply chain maps allows for improved visibility and traceability. An accurate, real-time representation of the product’s journey through its lifecycle makes it easier to identify inefficiencies and vulnerabilities and enables a rapid response to emerging problems[^11^]. Furthermore, the use of visualization tools can help stakeholders understand the relationships between various entities in the supply chain, fostering better collaboration and coordination.

Continuous Improvement and Monitoring

Implementing a traceability initiative is only the first step in the journey towards a more transparent and sustainable supply chain. Businesses must actively monitor and continually improve their traceability systems, addressing any identified inefficiencies or areas of concern. Frequent audits and assessments can help measure the effectiveness of the implemented system and ensure it remains up-to-date with the rapidly changing technological landscape.

Driving Sustainable and Circular Value Chains

Embracing traceability and sustainability principles can transform linear supply chains into circular value chains that optimize resource efficiency and promote a circular economy[^12^]. A circular value chain emphasizes recycling, reusing, and reducing waste, driving environmental benefits, and unlocking new revenue streams. Adopting a circular approach also encourages businesses to identify potential opportunities for product redesign, material substitution, and waste reduction, contributing to long-term profitability and sustainability.

Conclusion

Traceability and sustainability, powered by digital transformation, are crucial elements for supply chain resilience and competitiveness. By harnessing technology, embracing data-driven insights, and fostering collaboration, businesses can master the challenges of implementation and benefit from a more sustainable, transparent, and efficient supply chain. It’s time for organizations to take advantage of digital transformation initiatives and maximize their supply chain performance.